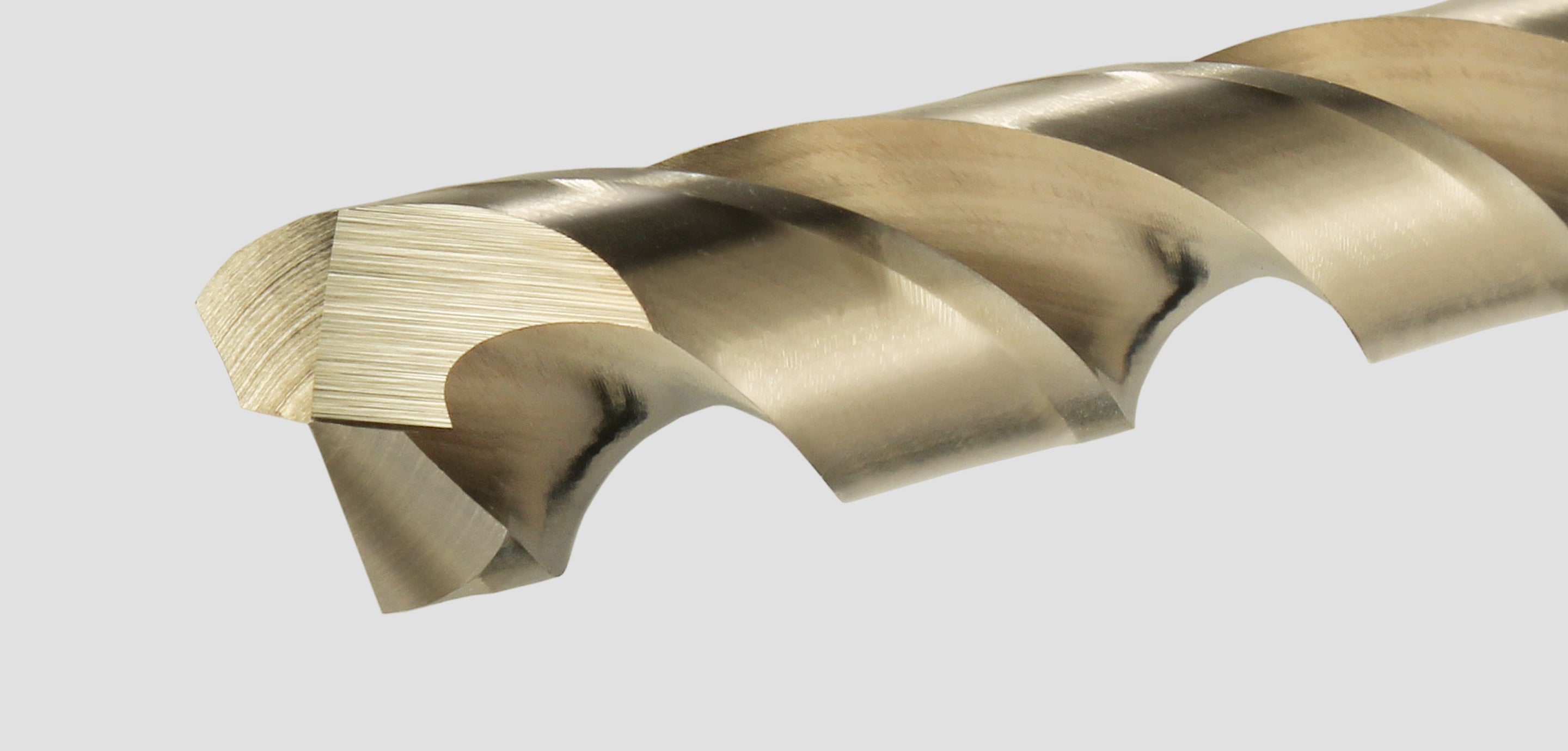

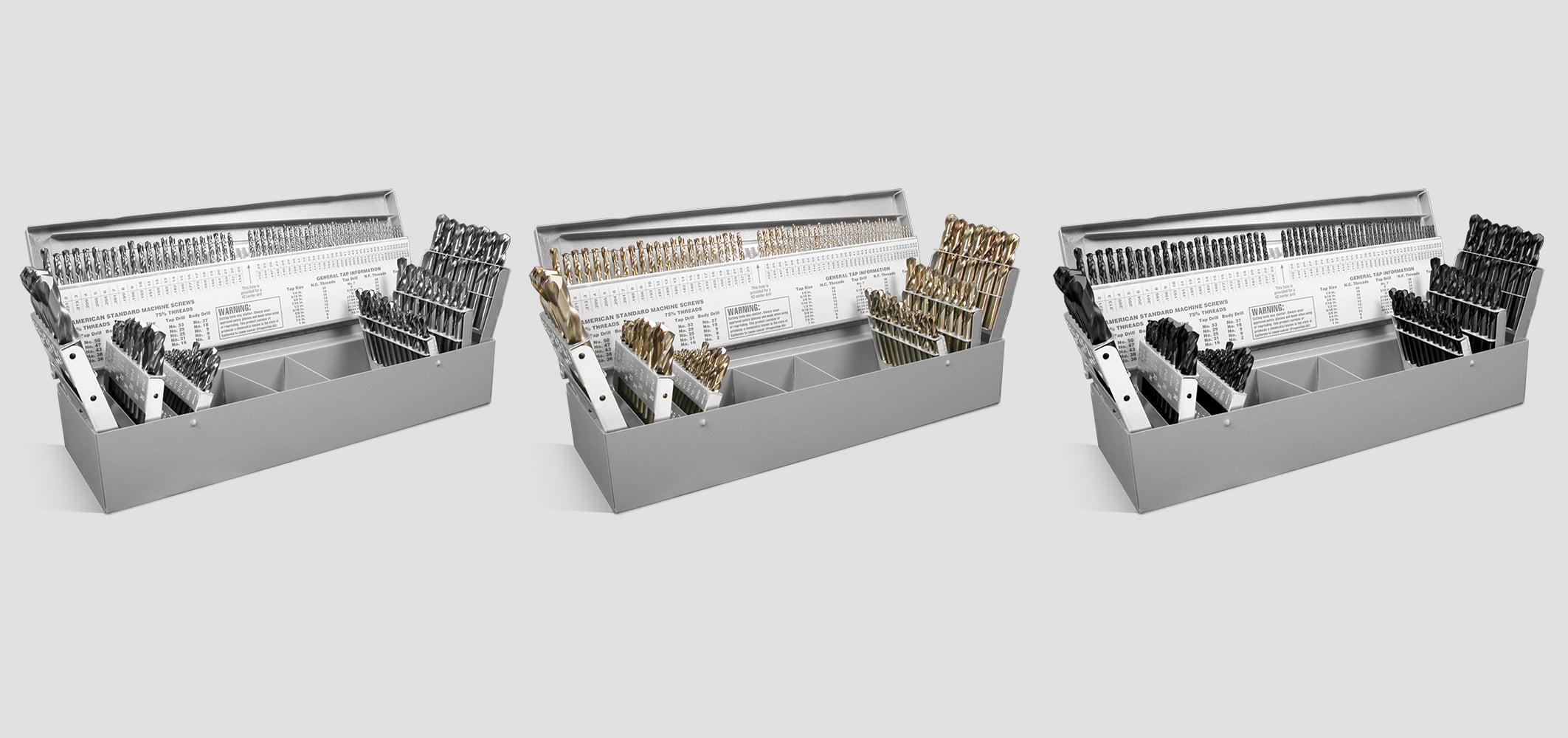

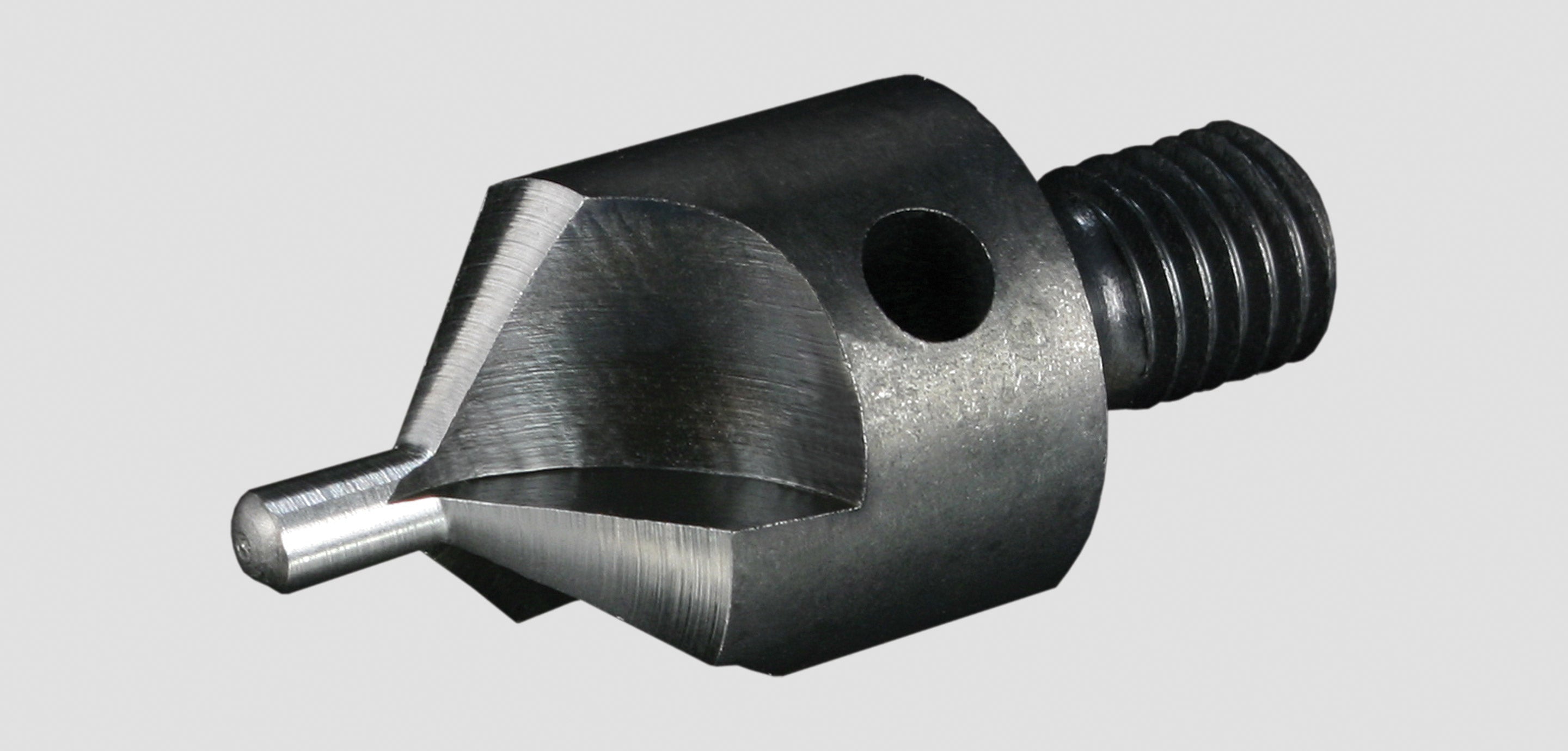

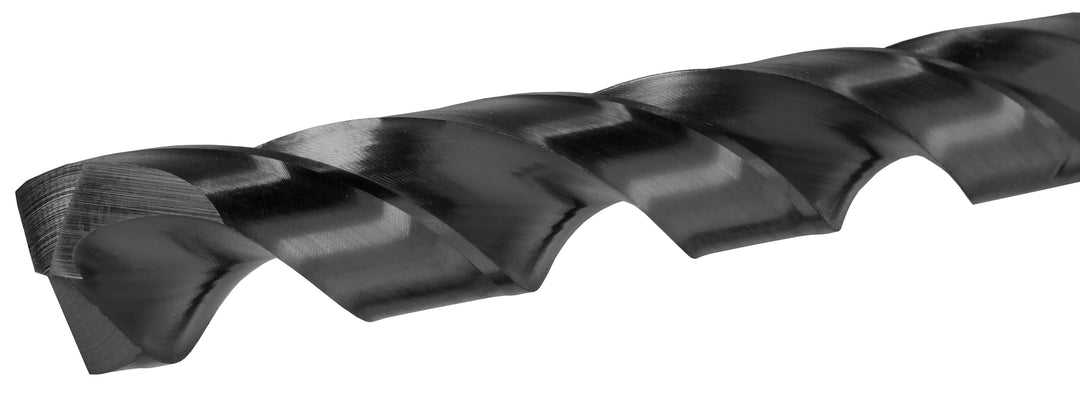

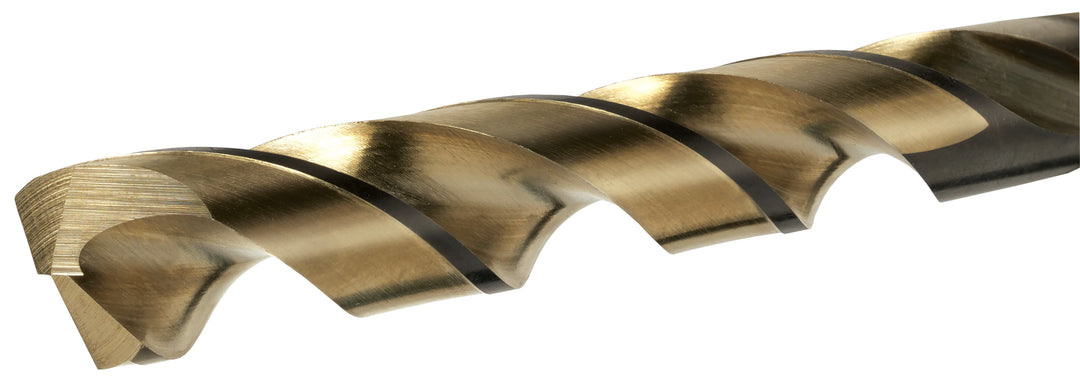

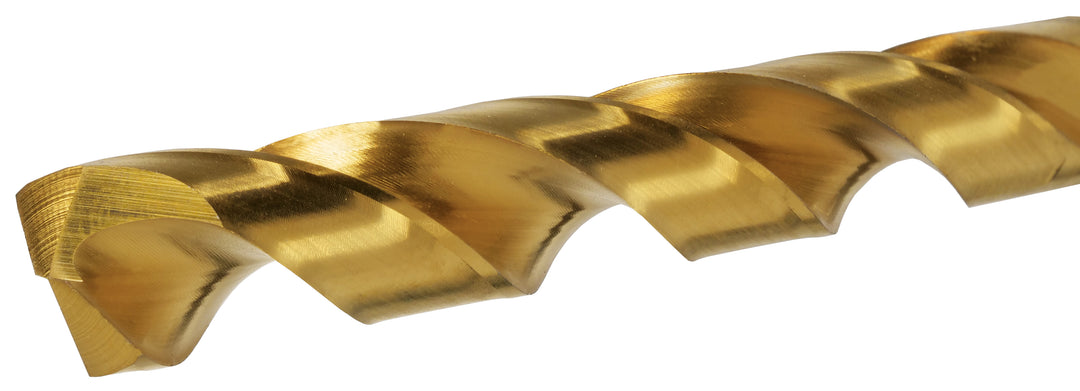

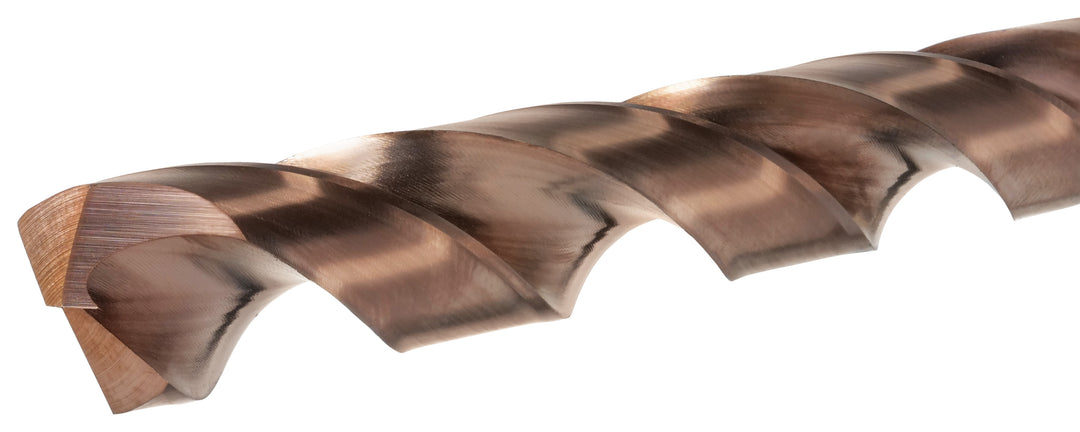

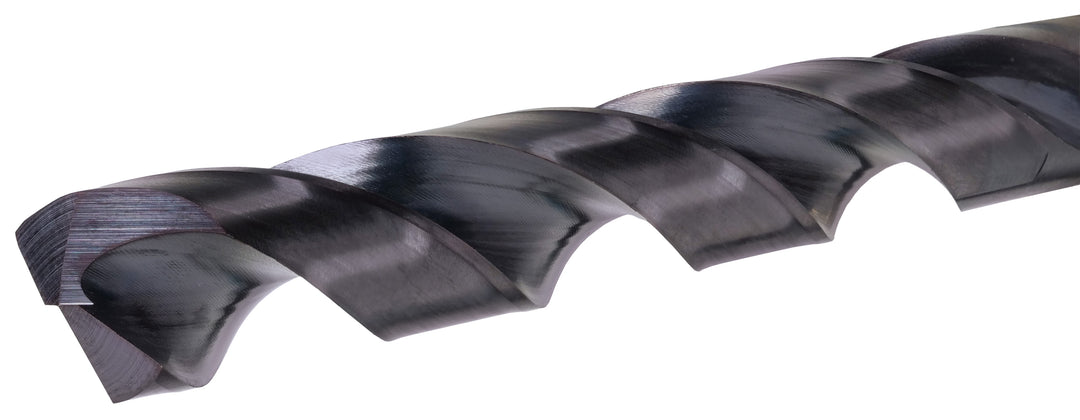

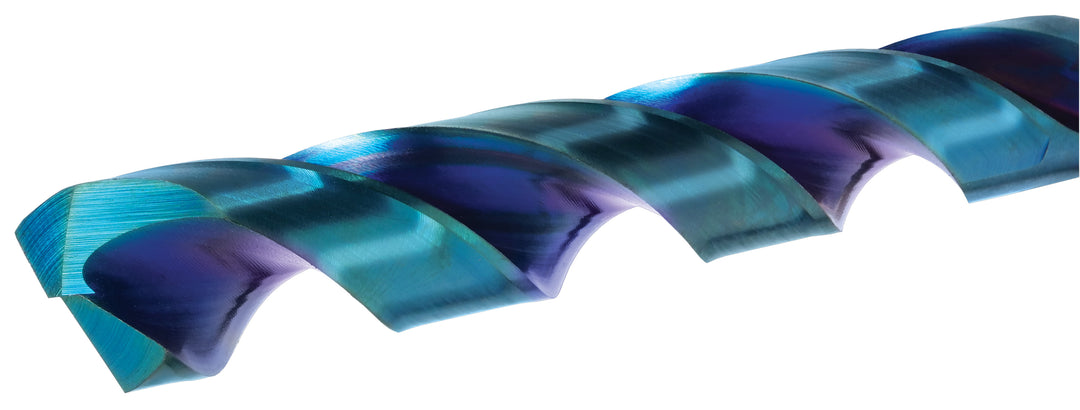

Coatings

We would love to help you with all of your coating and finishing needs. Below you will find all of the surface treatments that we currently offer. For pricing, capacity, and any questions you may have please use the form at the bottom of the page to email us or call us at

(866) 433-4768.